|

Call: +44(0)1234 841221 E-mail: [email protected] Case Study of Air conditioning Visit To Daikin Air Conditioning Factory in Oostende Belgium (06/11/14) Daikin

Air Conditioning Factory Visit 03/11/14 to 05/11/14

Orion air conditioning and refrigeration were invited by Daikin Air Conditioning UK to tour the European manufacturing factory in Oostende Belgium. The Oostend facility produces the Skyair, split, VRV-IV and Daikin Altherma air to water heat pumps used in homes and buildings for heating / DHW. The full range of Daikin Skyair and slit indoor units including FTXS, FTX, FHQ, FCQ, FAQ etc and a full range of Daikin air conditioning condensing units. They also produce the new Daikin air conditioning heat pump and heat recovery unit VRV-IV used for medium / large commercial and residential buildings. The production facility is spread over a 135000 metre square site which was donated to Daikin in 1984 by the Belgium government as a business incentive to bring manufacturing to the area. Since its conception as mainly as sales office the facility has grown into a modern production factory. The tour included a presentation of the corporate history, corporate ideals and expansion timeline of Daikin air conditioning from its conception in 1924.

Daikin Air Conditioning And Altherma Factory Production Quality: The Daikin air conditioning production lines are slowly being upgraded with robot technology taking the role of many of the heavy metal fabrication processes within the facility such as stamping out the base plates of the condensing units and side panelling. The factory is considered a world leader in air conditioning, heat pumps and air to water heat pump production processes with a high emphasis on producing a high quality product from the start with very little human error while reducing the need for problems occurring in the field which diminishes their brand reputation. All the indoor air conditioning units and condensing units manufactures are pressure tested on site with a Co2 / Helium mix to see if it holds pressure and then tested for capacity errors with outdoor units being tested with a applicable indoor unit of the same capacity to see if the system runs within correct cooling and heating parameters.

The large output systems such as the VRV-IV condensing units (8 HP+) are tested by a computer test run from minimum to full capacity settings. It is believed that no other manufacture rigorously tests their air conditioning equipment in such a high specification manner. Many of the cheaper air conditioning brands prefer to take the path that if their air conditioning product is not tested at the factory and the product fails in the field it can be replaced or corrected in the field leaving the liability of the error with the end user or engineering company installing it. This obviously saves the manufacture money as they do not require a test facility. This is why Daikin air conditioning is considered a world leading brand within the air conditioning industry as the air conditioning installer can be rest assured the product has been tested fully before installation. Rolling Production Supply Chain: The main factory floor is split between the stores and manufacturing where one side of the factory is the supply chain stores which picks parts for each individual systems in production whether a wall, ducted, floor or condensing unit. Once picked the factory operates a gravity feed tray system which rolls the individual trays to parts of the production process. This has saved on the need for folk lifts or other logistical vehicles for the most part. The factory production facility has a "no photography" policy so competitive companies do not replicate these production procedures. Daikin air conditioning produce their own parts including compressors (produced in Czech Republic) and most of its parts are sourced within Europe. Daikin Resource Centre: Daikin

air conditioning Oostende has a great resources centre which houses

working models of units giving the visitor a insight into the workings

of the units. There is a full range including a working Altherm unit

with under-floor exposed heating coils to standard Skyair models. Daikin Air Conditioning Units Produced At The Factory: The Oostend facility produces the following models: FTX, FTXS, FVXG-K, RXG-K, RZQG, FCQG, FHQG, FXZQ, FXDQ, FTXG, FXAQ-P, HXHD, RXYRQ-P, FWC-B, FWF-B, UATYQ-C, ECONO, RXHQ-P and all Altherma models. To

Buy Daikin On-line visit our website http://www.orionairsales.co.uk

Orion air conditioning and refrigeration limited is a United Kingdom based distributor of environmental products including air conditioning, heat pumps, electric space heaters, gas space heaters, oil space heaters, air exchange units, dehumidifiers and refrigeration equipment.

Residential, commercial and industrial heaters. Portable and fixed space heaters with something for everyone from the 500W to 100kw. We have one of the most extensive heater selections from patio heaters, fire places, propane heaters, oil filled radiators, fan heaters, oil heaters, gas heaters and infrared.

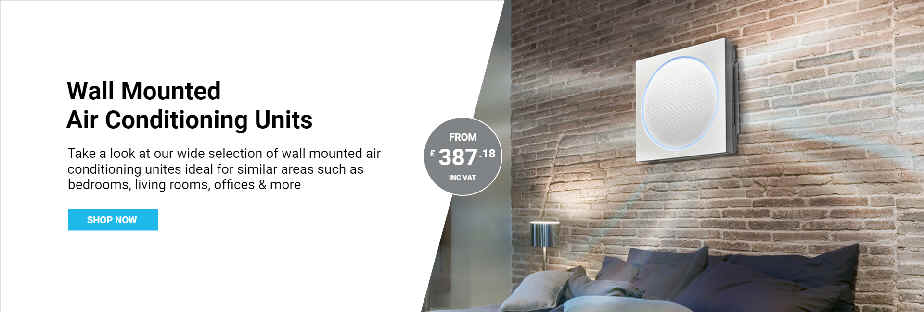

Wall

mounted air conditioning is the most popular type of air conditioning

system. Versatile and easy to install, most wall air conditioning units

have a filter which destroys funghi, collects duct in the air, bacteria

and viruses which provides healthy clean air for the occupants. Modern

wall air conditioning units have Innovative inverter

compressor designs and the ozone friendly R410A and R32

refrigerants combined with low noise air movement fan arrangement. The

result is a quiet, high performance cooling and heating system,

with advanced electronic controls for maximum comfort, controllable and

energy efficient.

The Olympus Appliances JetHeat series of portable commercial / industrial electric fan heaters are designed for use in workshops, schools, warehouses, nurseries, showrooms, storage rooms, construction sites and containers. This series is made to a high standard and features a 3Kw / 240V and 9Kw / 415V, 15Kw / 415V and the largest 30Kw in 3 phase 415V format.

Designed to give the greatest possible safety, performance and reliability even in the most demanding industrial and commercial applications. Housed within the high-grade steel bodies and sickle bladed fans, designed to maximise airflow and pressure, which are driven by aluminium motors that keep weight to a minimum. Ideal for ventilation, extraction and fresh air supply as well as dust and fume extraction. Available in standard and explosion proof 110V and 240V~50Hz.

Projects And Tendering:

Orion air conditioning and refrigeration offer an UK installation, service and maintenance on Industrial, commercial refrigeration and air conditioning. Spare parts supply on Bitzer, Copeland, Prescold, Carrier, Carlyle, Dorin, Prescold, Frascold, Gram, Grasso, Hubbard, Maneurop, Trane and Sabroe. Air conditioning and refrigeration spare parts from all the manufacturers including fan blades, thermistor probes, compressors, scroll compressor, Inverter compressor, swing compressor, Inverter Pcb, printed circuit boards, air filters, fan motors, thermisters, drain pumps, remote controls, expansion valve, condensor coil, solenoid valve, crankcase heater, electronic thermostat, float switch, magnetic contactor, capacitor, high pressure switch, low pressure switches and PCB's, PWB's.

Contact Us:Sales Installation and Service

UK: +44 (0)1234 841221

|