|

Wet Well Pumping Stations

|

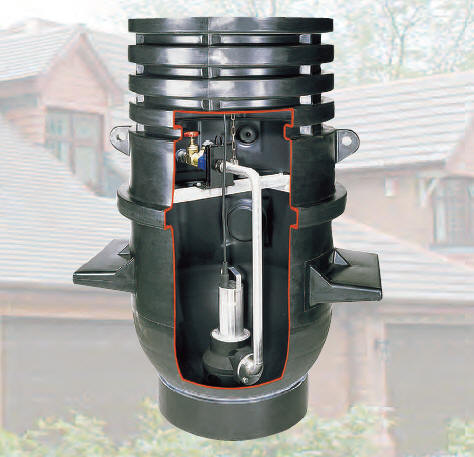

Wilo Drain lift WS900 1100 Sewage

Pumping Station

Fully

self-contained wet well sump pump station with

internal pipe work, valves and fittings. WS900 for

single pump applications and WS1100 for either

single or twin pump applications. Two sizes of

chamber for five different pump options. Fully

self-contained wet well sump pump station with

internal pipe work, valves and fittings. WS900 for

single pump applications and WS1100 for either

single or twin pump applications. Two sizes of

chamber for five different pump options. |

Heavy duty

construction of recycled PE material

2/4 anti-bouyancy

fins as standard (no concrete ballast rings required)

2 or 4 inlets

On site determinable

Spherical sump

bottom to prevent solid build up

Wilo above the

water auto coupling arrangement

2 no. DN100

socket spigots for foul water connection

Easy to remove

vertical float bracket without disturbing float

settings

2-pedestrian

rated access covers available (standard lockable and

flood proof

type)

Economy version

available (integral float control on pumps no

control panel)

Storm water Attenuation and Rain

Harvesting Systems

| A

range of horizontal storage tanks manufactured

from heavy grade GRP material with internal

pump(s) and pipe work for water transfer and

pressure boosting. Standard underground Rain

harvesting system from 1200 to 12000 litres.

Attenuation tanks standard range up to 100,000

litres (other sizes available). |

Various pumps options available:

Wilo STS, TPs,

range + EMU FA range (water transfer) installed with

guide rail type system for easy removal of pump sets

Wilo TWi

stainless steel multistage submersibles for pressure

boosting

Single and twin

pump arrangements

Access openings

sized to suit pump sets

Pedestrian rated

cover included as standard, other cover ratings

available on request

Wilo Drain lift WS40, WS50, WS65 Waste

Station

| As

with the WS900 and WS1100 single and twin pump

options available for dewatering and sewage

removal applications. |

Can be installed

to internal and external of buildings

Single pump

chamber 200-litres storage

Twin pump chamber

400-litres storage

Package is

complete with DN100 hole cutting kit and inlet seal

for easy installation by site engineers

Wilo above the

water auto coupling arrangement

Synthetic chamber

material manufactured from recycled PE Wilo Pump

options Wilo STS models, TP units and EMU FA 50mm

units.

Wilo Drainlift WS GRP Pumping Stations

| Vertical

self-contained wet well sump pump station with

internal pipework, valves and fittings.

Manufactured to order to suit sewage, foul water

and stormwater applications. Tank diameters can

vary between 1250, 1500, 1800, 2500 and 2900mm.

Depths of tank can vary from 1000mm to 6000mm.

Single and twin pump options (3-pump stations

available upon request). |

Heavy duty

construction of pre-formed GRP material

Benched sides to

prevent solid build up

Wilo guide rail

type arrangement for easy servicing of pumps

2 no. DN100

socket spigots for vent and cable duct connections

Various size and

number of inlet spigot connections available

Pump options

Wilo STS, TP units + EMU FA units All sizes

Various access

covers and ratings available

Short

manufacturing lead times (typically 2-4 weeks)

Choice of

internal pipework materialUPVc, galvanised or

ductile iron

Submersible Pumps

Wilo

TP50 TP65 Wilo

TP50 TP65

50mm

65mm pumps, Vortex & channel impellers,

pump manufactured from composite material, INOX

motor. |

|

EMU

FA05-FA60

50mm - 600mm pumps Vortex &

channel impellers, cast iron construction, special

seals and coatings available. ATEX rating pumps

available on request. |

|

Wilo

MTS40 + MTC32-40 Wilo

MTS40 + MTC32-40

Macerator pumps 32 & 40mm,

cast iron & INOX heavy duty construction.

|

|

Wilo

STS40 - 65 Wilo

STS40 - 65

40mm and 65mm pumps, Vortex &

channel impellers, pump manufactured from cast

iron, INOX motor.

|

Wilo Pump Station Questionnaire

|

Type of Liquid |

|

Surface Water / Foul |

/ Sewage |

Application and Daily Flow |

|

L/S, GPM. M3h |

|

Pump Arrangement |

|

Single / Twin |

Electricity Supply |

|

240v, 415v |

|

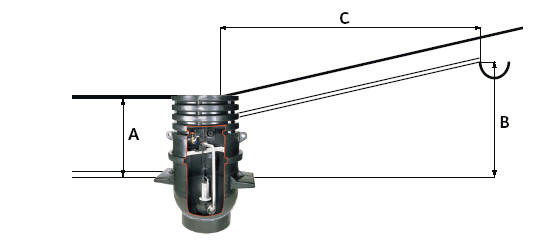

Distance from Sump Base to Panel |

Location |

|

Mtrs |

Type of Manhole Cover |

|

Pedestrian, Heavy Duty |

|

Number of bends in Rising Main |

|

Material and size of Rising Main |

|

Pump Station Storage below

Incoming Sewer See building regulations

section H1 to conform |

Vertical Distance from Ground

cover to Incoming Sewer (See A) |

|

Vertical Distance from Pump Sump

to Discharge Invert (See B) |

Vertical Distance from Pump Sump

to Discharge Point (See C) |

|

Other information |

|

|

|

| |

|

|